Brand Name: HTEG

Model Number: CFB steam boiler

Place of Origin: Shandong, China (Mainland)

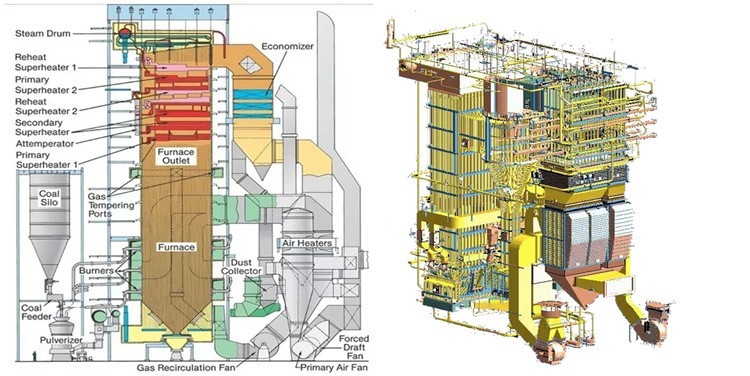

High thermal efficiency power station 260 t/h circulating fluidized bed steam boiler

Specification

Better performance circulating fluidized bed boiler is of low-temperature combustion, therefore, nitrogen oxides emissions of such boiler is much lower than that of coal-powder boiler, and such boiler could directly desulfurized during combustion process. Circulating fluidized bed boiler with high desulfurization rate is economical.

Parameter

Model |

SHX4-1.25-A |

SHX6-1.6-P |

SHX8-2.5-H |

SHX10- |

SHX12-2.5-W |

SHX15-2.5-A |

SHX20-2.5-W |

Rated evaporation |

4 |

6 |

8 |

10 |

12 |

15 |

20 |

Rated steam |

1.25 |

1.6 |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

Rated steam |

194 |

204 |

226 |

450 |

226 |

226 |

226 |

Feed water |

105 |

104 |

104 |

105 |

70 |

105 |

104 |

Design fuel |

Bituminous |

Lean coal |

Lignite |

Bituminous |

Anthracite |

Bituminous |

Anthracite |

Package mode |

Bulk |

Bulk |

Bulk |

Bulk |

Bulk |

Bulk |

Bulk |

Features:

Wide adaptability of fuel (all kinds of coal quality); clean combustion (high efficiency, desulfurization, reducing emission of NOX ); excellent performance for load adjusting; comprehensive application of ash & slag.

The Accessory

It utilizes stationary design theory and CFB technology spectrum, to optimize and decrease the total stock of CFB with the Theory of Material Balance and Large Particle Combustion Theory, thus forms energy saving circulating fluidized bed technology based on the reconstruction of fluid state. Through fluid state of CFB boiler reconstruction, to reduce auxiliary power and improve availability, while keeping CFB technology advantages of strong coal adaptability and low pollution control cost.

Inquiry now

Our Company